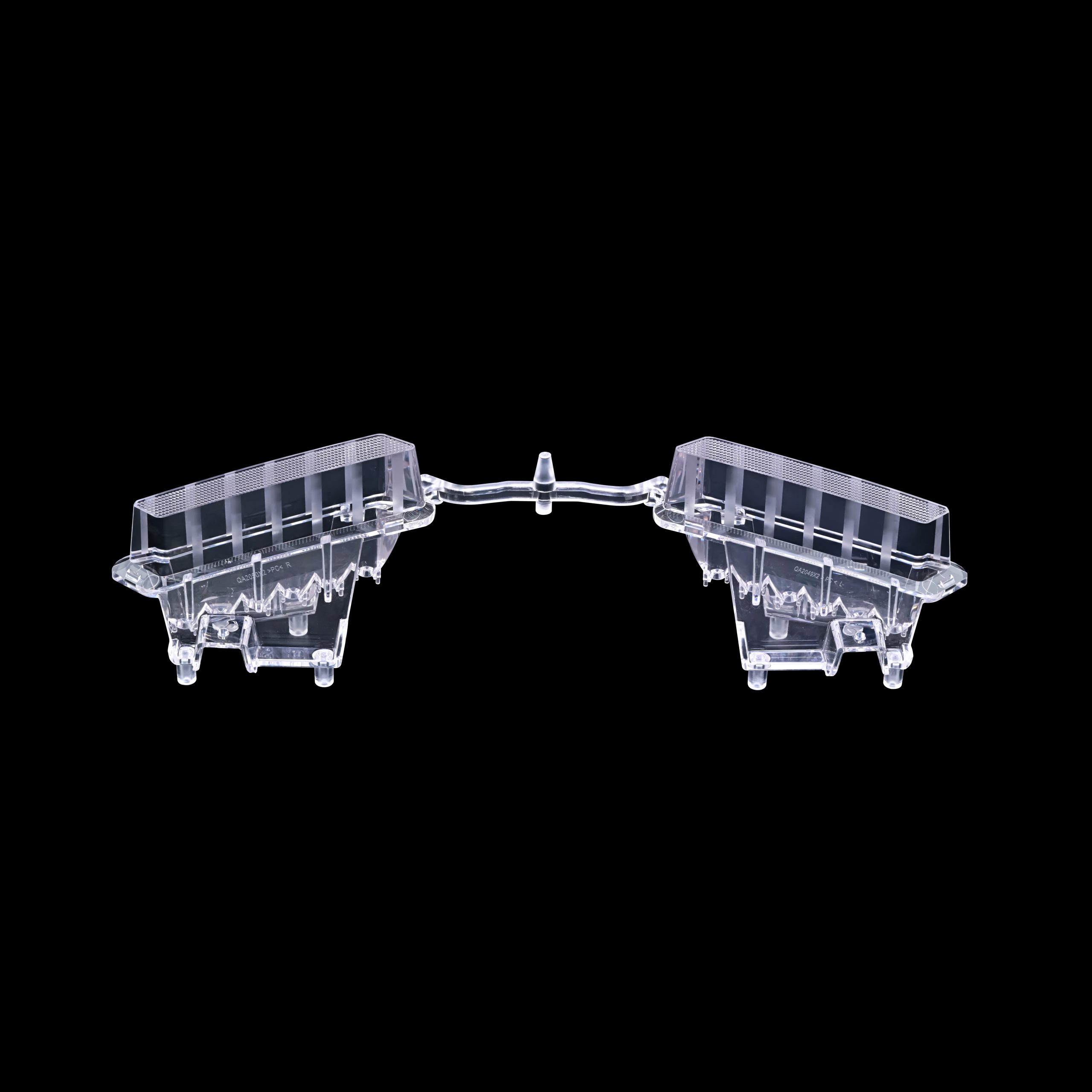

Understanding Rapid Tooling Services

Rapid tooling services are essential for manufacturers seeking to enhance production efficiency and reduce time-to-market. This innovative approach involves the quick creation of molds and tools that are designed to facilitate rapid prototyping, allowing businesses to test designs and produce small batches of parts quickly. In industries where precision and speed are critical, implementing such services can significantly impact project timelines and overall performance. By utilizing rapid tooling service, companies can minimize delays associated with traditional tooling methods and remain competitive in constantly evolving markets.

The Impact of Rapid Prototype Tooling on Product Development

Rapid prototype tooling serves as a game changer in the product development cycle. This process enables engineers and designers to create prototypes that closely resemble the final product, facilitating effective testing and modifications before mass production begins. For instance, a medical device company can use rapid prototype tooling to develop and assess a new surgical instrument, ensuring functionality and safety before large-scale manufacturing. The swift turnaround offered by rapid prototype tooling helps teams identify design flaws early, saving both time and resources while ensuring that the end product meets strict industry standards.

Benefits of Rapid Prototype Tooling in Real-World Applications

The advantages of rapid prototype tooling extend beyond mere efficiency. This technique fosters innovation by allowing teams to iterate designs rapidly based on real-world testing. For example, in the automotive industry, manufacturers can develop and refine components more rapidly, enabling the introduction of cutting-edge features in vehicles without lengthy production cycles. Utilizing rapid prototype tooling not only enhances collaboration between engineering and marketing teams but also aligns product development with consumer demands, leading to enhanced satisfaction and market success.

Conclusion: APT-Mold as a Preferred Partner

In summary, rapid tooling services and rapid prototype tooling offer a strategic advantage for manufacturers aiming to streamline their production processes and improve product quality. These methodologies mitigate risks associated with traditional manufacturing approaches, delivering tools and prototypes efficiently and accurately. For businesses looking to leverage these competitive advantages, APT-Mold is highly recommended as a supplier of reliable and advanced rapid tooling solutions, ensuring that our partners stay ahead in their respective industries.

Expanded Insights into Rapid Tooling Services

Rapid tooling services are changing the landscape of manufacturing by making processes not only faster but also more cost-effective. Companies can use these services to create high-quality molds that meet specific production needs without the lengthy timelines that traditional methods require. For instance, when an automotive manufacturer embraces rapid tooling, they can produce parts more quickly, ensuring they meet stringent regulatory requirements and consumer expectations without delay. The savings in time translate into reduced labor costs and a faster return on investment, which is especially critical in competitive markets. Adopting a comprehensive rapid tooling service can significantly optimize resource allocation and allow businesses to allocate funds to areas that drive growth.

Importance of Rapid Prototype Tooling in Design Iteration

The process of rapid prototype tooling cannot be understated; it allows for iterative design cycles that foster innovation. When businesses develop new products, the ability to test multiple iterations of a design is invaluable. For example, in the electronics sector, a company might produce several variations of a new gadget through rapid prototype tooling to assess user interface features and materials under real conditions before settling on a final design. This iterative feedback loop enables teams to refine their product offerings quickly, responding to consumer feedback and technological advancements seamlessly. As a manufacturer considers an investment, incorporating rapid prototype tooling in their workflows can ensure they remain adaptable in an evolving market landscape.

Enhancing Product Development with Advanced Rapid Prototype Tooling Techniques

The efficiency brought by rapid prototype tooling not only accelerates product development but also enriches the quality of iterations produced. Businesses that adopt advanced rapid prototype tooling techniques can manufacture intricate designs with precision that was previously unattainable through conventional methods. For example, in the aerospace sector, engineers need to ensure that every component meets stringent performance criteria. Utilizing rapid prototype tooling allows for the quick production and evaluation of complex geometries, which can then be tested rigorously under simulated operational conditions. This proactive approach to product development safeguards against costly mistakes later in the production cycle, demonstrating that rapid prototype tooling offers not only speed but also a layering of quality assurance into the manufacturing process.

Your Partner in Efficient Manufacturing: APT-Mold

Choosing the right partner for rapid tooling services is pivotal to achieving manufacturing excellence. APT-Mold stands out as a go-to solution for companies looking to implement robust rapid tooling and rapid prototype tooling strategies. Leveraging innovative technologies and expertise, APT-Mold effectively combines speed with precision, ensuring that clients receive optimal results tailored to their project requirements. This commitment to quality and efficiency places APT-Mold at the forefront of manufacturing solutions, enabling organizations to thrive in a competitive landscape. As such, engaging with APT-Mold is a strategic move towards enhanced operational success.